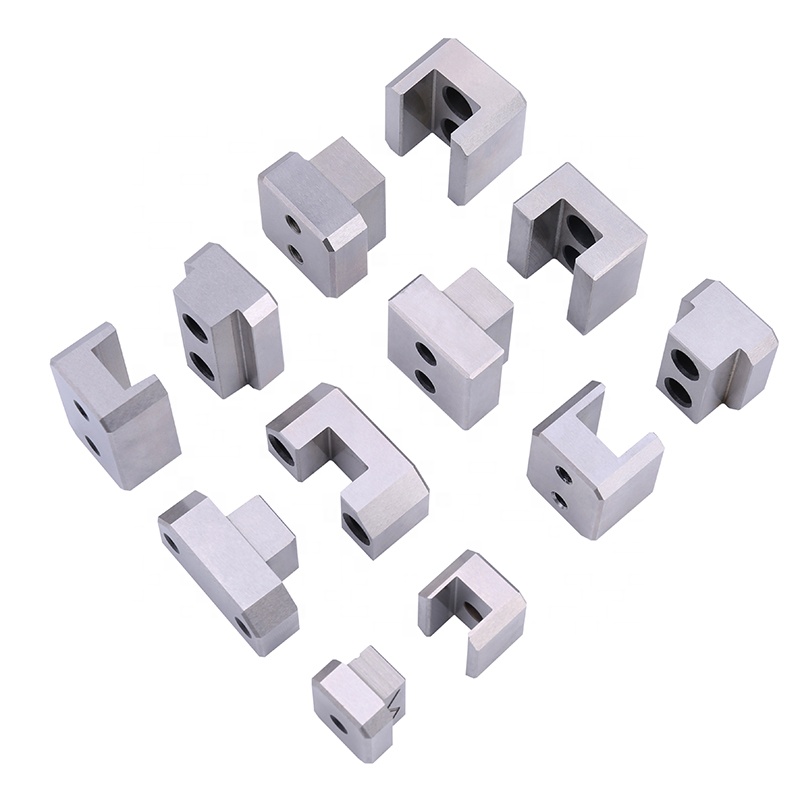

Material | Steel:HSS , ASP23,Carbon steel, ASSAB Steel, 1.2379, Q235, 1.2842, C45# etc. |

Stainless Steel: 303 / 304 / 316 / 416 / etc. |

Aluminum: AL7075,AL6061,AL5052 etc. |

Titanium: Grades 1-4 Grade 5 Grade 9 etc. |

Tungsten Carbide:YG6, YG6X, YG8, YG8x, YG8A, YG8N, YG10, YG13X, YG13, YG15X, YG15, YG18X, YG18, YG20 etc. |

Brass,Copper,Bronze etc. |

Plastic: ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek etc. |

Surface treatment | Polishing, Sandblasted,Anodizing, Chrome plating, Zinc plating, Nickel plating, Laser engraving, PVD coating etc. |

Our Equipments | CNC Machining Center, 4 sets CNC AUTO Lathe Machine, 4 sets CNC Milling Machine,4 sets Drilling Machine, 8 sets Grinding

Machine,EDM Wire Cutting etc. |

Inspection Equipment | Japan Projector, Microscope,2D Projection,Height gauge,Micrometers,vernier caliper,Plug Thread Gages,Ring Thread Gages etc. |

Accuracy | Accuracy Of Machining:+/-0.005mm, Accuracy Of Grinding:+/-0.005mm,Surface Roughness:Ra0.4,Parallelism:0.01mm,Verticality:0.01mm

Concentricity:0.01mm |

Surface Roughness | Ra0.1-Ra3.2/ Also can be customized |

Leading Time Guarantee | A day's delay upon our ETD, 1% compensation, by parity of reasoning, up to 10% |

Quality control | IQC---PQC---OQC |